Jay,

"There is the distinct possibility that some of these "young engineers" will be lucky enough to end up in the automotive industry, from which they will be promptly expelled should they suggest beam axles on a sports/race car. My current car has a rear beam, and yes it is fantastic on a nice smooth road..."

Doesn't this worry you? It worries me, although more for my kids' sake than for myself.

As you say, beams work fine on smooth roads. Yet a young engineer will be ridiculed for suggesting one on a car intended for smooth roads (probably not "expelled", what with IR laws, etc...). Why? Simply because of the mindless following of fashion by his peers and superiors.

The really bizarre (humourous?) thing about this, is that all these passionate, almost religously zealous views, held by supposedly sober, rational engineers, are about nothing more than a "bunch of pipes". Different suspension = different bunch of pipes. If any arts, law, or med students, or for that matter, butchers, bakers, or candlestick makers, read these posts, I very much doubt they would understand why all the fuss. Why all the drama queens? Why are they arguing about different bunches of pipes???

(Answer to "Why?" at bottom...)

~~~o0o~~~

Tony,

In an earlier post you wrote.

"For a first effort, keep it all very simple and very conventional."

I agree entirely with the intent of that comment, namely KISS.

However, "very conventional" in FSAE is about as complicated as you can get. Namely, Double-Wishbone-With-Push/Pullrod&Rocker (let's call it DWWPP&R). Sadly, peer group pressure keeps forcing new students down this complicated path.

I am trying to help the new students by pointing out that there are, in fact, much simpler suspension types that are suitable for FSAE. Might get around to discussing that one day...

~~~o0o~~~

Olly,

"The ADFA beam axle car was designed using a clean sheet approach ...

... to muster up the courage to do something very different to the accepted norm."

Firstly, you deserve a medal for "extreme courage under fire" for taking that route. Honestly, and unfortunately, it seems there are very few people left in this world who are prepared to make such tough decisions.

Secondly, I wish you would have called me a few more times. I might have been able to help you get over those first few hurdles (camber compliance, steering, etc.) a bit more quickly.

Thirdly, the reason I came back to this forum is that I saw that there was at least one student in tens of thousands who was actually prepared to think things through for themself, rather than simply follow the flock. There is hope!

(Ooops..., perhaps I shouldn't have written that third one. Now the lynch mob might be coming down your street. Sorry!)

~~~o0o~~~

js10coastr,

"wah wah wah wah Look at me I'm the smartest man in the room! wah wah wah wah"

Yep, that's straight out of the movie "Idiocracy". Well done.

~~~o0o~~~

Matthew,

"Designing with the ease of manufacture in mind allowed a small team to build a car around the constraints and still get testing and driver training done so that we didnt look too bad on track."

Thanks for further "real life" confirmation that KISS works. If a large enough "critical mass" of teams keeps proving that KISS is really good, then eventually the rest of the students might believe it.

~~~o0o~~~

exFSAE,

"When I want to pull up a map and figure out the distance to get from my home to the local deli, ...

... I can approximate it as a 2D planar problem and get an answer quite sufficient to my needs."

I have covered this before, but once again...

The key thing is that YOU KNOW that the world is round. So do kindergarten kiddies, because it is a simple concept. So if you have to build a really big bridge, or shoot rocketships into space, then YOU KNOW you will have to move from the 2-D approximation to something 3-D.

Here are your words from another thread (re: TLV).

"... there are known knowns; there are things we know we know. We also know there are known unknowns; that is to say we know there are some things we do not know. But there are also unknown unknowns – there are things we do not know we don't know.

It's that last one that will get ya."

I very much agree with that! I have simply been pointing out (mostly on other threads) that many students of automotive kinematics "do not know what they don't know" (ie. that there is a whole world of interesting, and more accurate, and useful, kinematic theory out there).

"... working out all this stuff in your head is a waste of time...

... No time to waste."

This is a bit off-topic (covered elsewhere), but knowing the approximate location of a suspension's ISA requires negligible "working out", and at most can be done with simple software. Importantly, once you know the ISA's location, you can tell "at a glance" many of the behavioural properties of the suspension (eg. anti-roll/pitch, jacking, toe/camber/castor changes with bump, etc.). Briefly, there are very good places, and very bad places for it to be. And an inbetween area where you have to check the details...

It is a very useful tool, is easy to use, and can save a lot of time. Why the reluctance to use it?

~~~o0o~~~

To students interested in winning FSAE by using simpler suspensions.

As should be obvious from the above, you will get a lot of flak from both your peers and the Design Judges, if you go down this path. As Olly said above, "The [beam-axle] car was received very sceptically at its first competition and design event."

You should expect something like;

Design Judge, "So, Suspension Boy, what do you have here???"

Suspension Boy, "Well, Sir, due to our limited resources we decided to avoid all the complexity of double-wishbones, especially with their seemingly unnecessary push or pullrods and rockers. We couldn't find any reasons why we needed ..."

Design Judge, interrupting, "What the!!! How the hell do you expect to score points in this Design event, with such a NEGATIVE and PESSIMISTIC attitude! Geez ..."

Hopefully by discussing this heresy here the Design Judges will be somewhat "softened up" to these concepts when you bring your cars. It won't be such a shock to their systems. Also, going through the various pros and cons of different suspensions, in a rational way, might help when you are "defending your decisions".

~~~o0o~~~

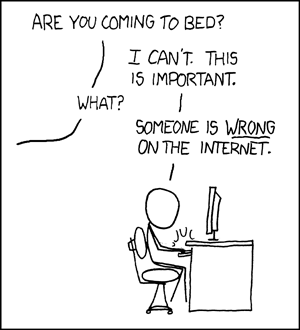

Finally, why the extreme resistance?

Well, IMO it is indirectly due to the success of previous generations of engineers, particulary with regard to mechanised farming. Put simply, full stomachs = empty heads. With an abundant food supply, effort is no longer needed.

If "necessity is the mother of invention", then with no necessity, there is no invention. Everybody gets by just fine these days, simply doing the same-old-same-old...

Z

|

|

Reply With Quote

Reply With Quote