<BLOCKQUOTE class="ip-ubbcode-quote"><div class="ip-ubbcode-quote-title">quote:</div><div class="ip-ubbcode-quote-content">Originally posted by Fyhr:

[QUOTE]Originally posted by Kyle "steering and suspension":

i have seen other teams use a similar system, do you find this gives you less play than a simple intermediate shaft with universal joints of some kind? how do you adjust your clearance between rack and pinion? </div></BLOCKQUOTE>

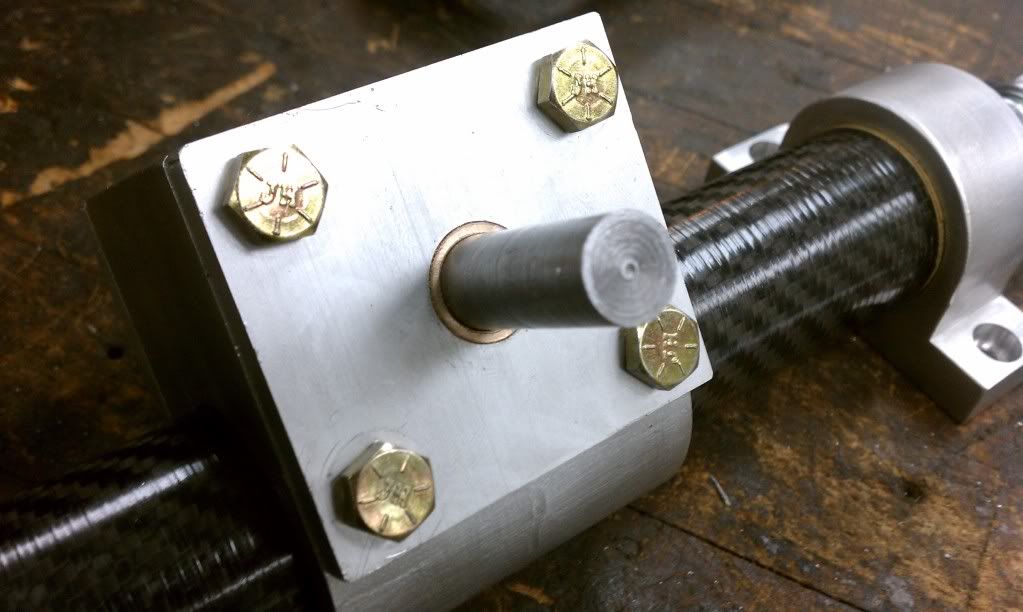

The first revision used flat solid shims between the pinion bearing lids, the second revision used hard rubber shims to allow higher tightening running with higher interference while retaining some elasticity to avoid lockup (if i recall correctly).

The bevel gear does not give less play than any other solution, in our case it was a large source of play, especially after running for a few competitions. I believe the reason it performs poorly is the bevel gears only being held by a keyed joint, with no possibility to shim the gears together. In a recent discussion with a transmissions professor he suggested using belville washers for shimming the gears together, yet again allowing high interference without lockup, this would however increase friction in a steering system that is already fairly grave.

The reason we used this solution is packaging, on these cars we've run 10" wheels with 7 deg caster, there was simply no room for the steering arm low-front on the upright.

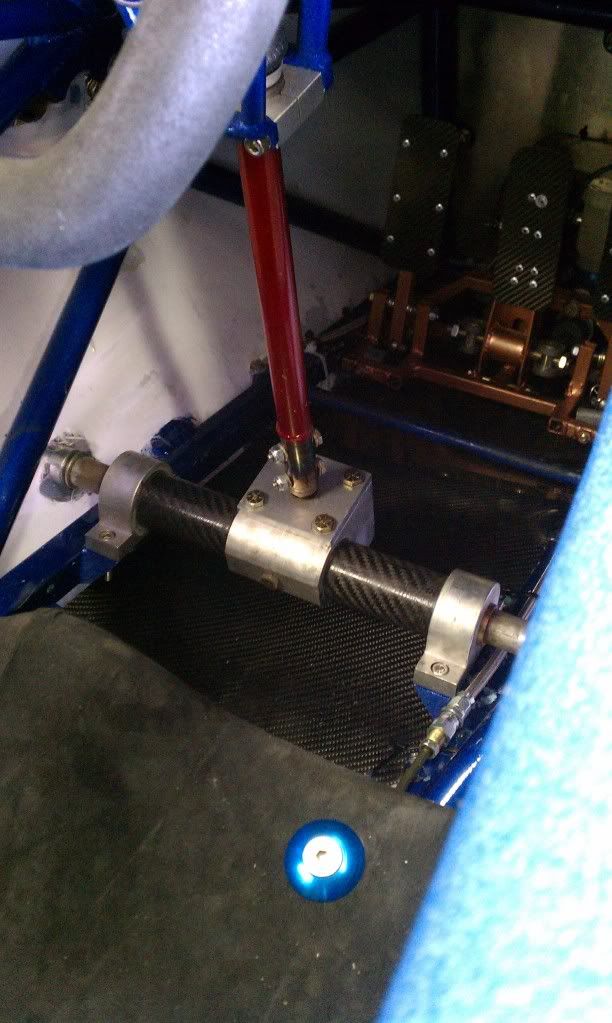

On the most recent car, the team have moved away from the 90deg gear and run low-front

steering in 13" wheels, here is the rack.

We also purchase our gear components, again if i recall correctly, we've used modulus 1.5.

|

|

Reply With Quote

Reply With Quote