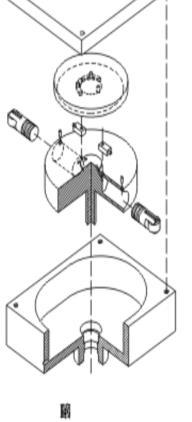

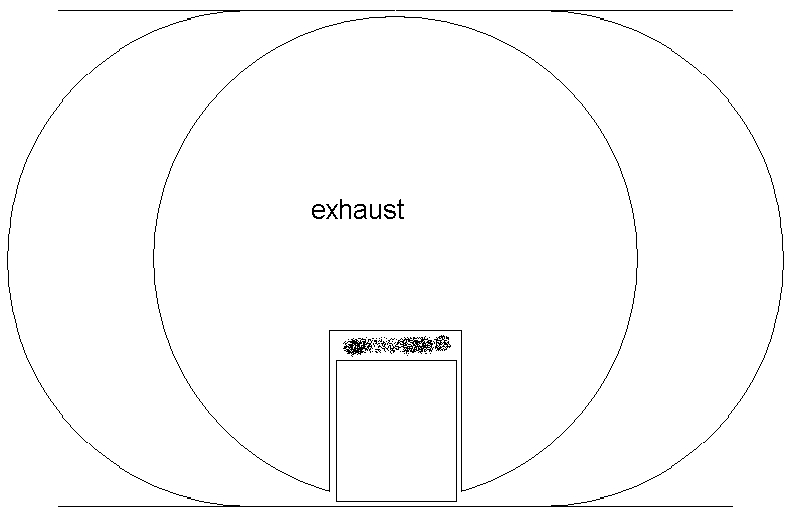

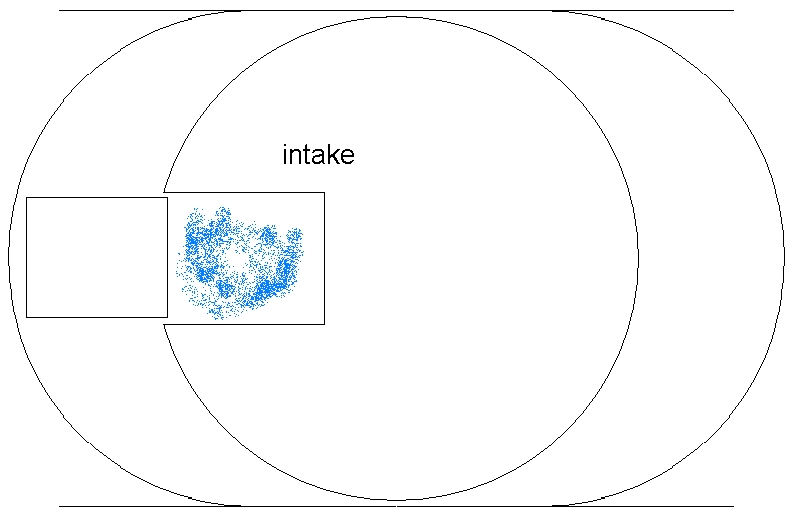

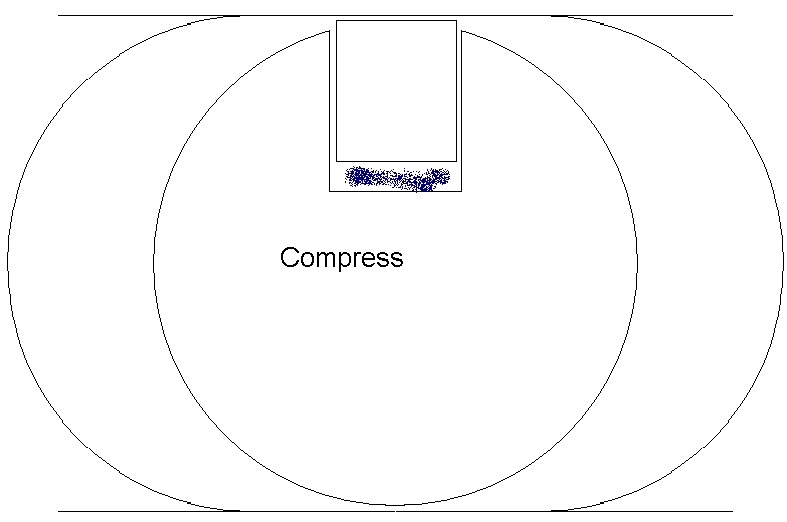

Is it piston engine or not?

|

|

|

|

Is it piston engine or not?

Is it piston engine or not?

beautiful

that things gonna shoot a piston straight out of the case when it misfires

the thing with these engines the more problems they solve the more they create

Hiren G Patel

FS – Orion Combustion (Founder Member)

-------Prototype '06

-------Powertrain Lead '06 '07 '08 '09

-------Composites guy '10

-------Technical Director '10

-------Technial Advisor/Mentor '12

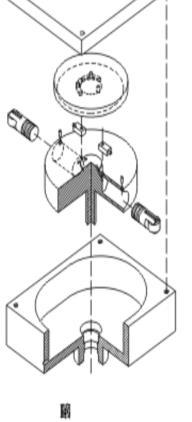

Seems like the component of force turning the crankshaft is also working very hard to cock the piston sideways in the bore. Or shear it in two with a massive bending moment.

Also it's made in Taiwan. Don't get me wrong, they make top notch fake plastic dog poop, i just don't have high hopes for their engines.

Matt Brown

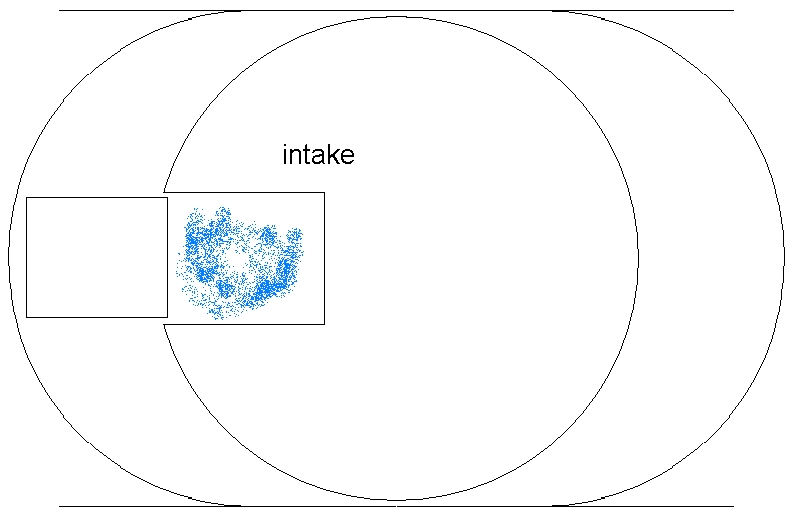

Imagine if this design was the design we used in everyday life

Then someone came up with this single piston with 3 different kinds of rings to make it seal, and with a connecting rod to transfer torque to a spinning crank, and you had to have this camshaft(s) with complex curvature lobes turning half the speed of the crank pushing these valves with springs holding them up and you had to have these pressure fed bearings for the mains and rod.

We'd think we were adding complexity, but...

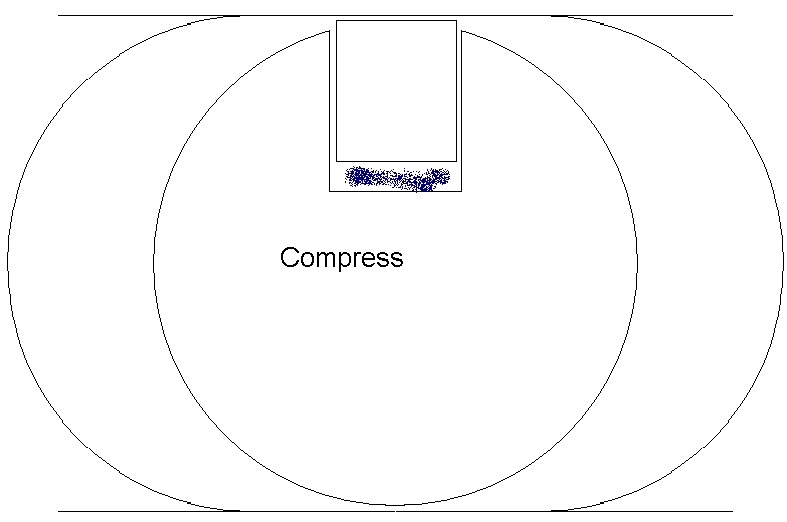

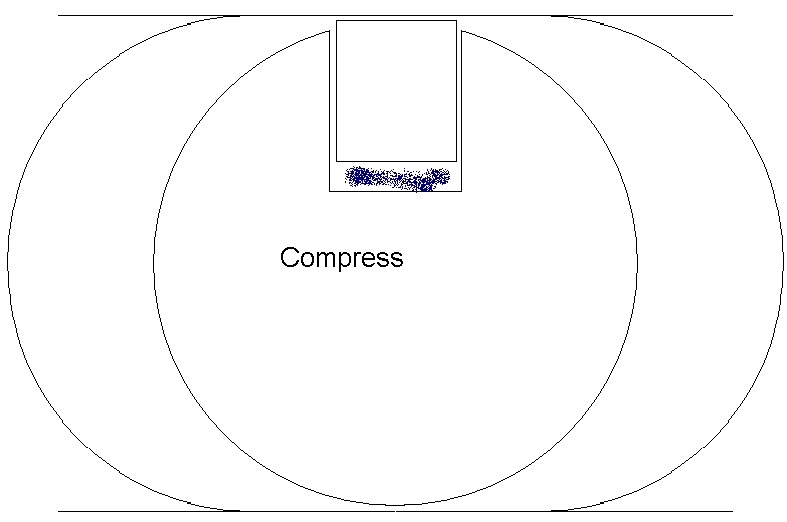

Like Matt said, the effective rod length is now the radius of the roller leading to way higher thrust loads on the piston.

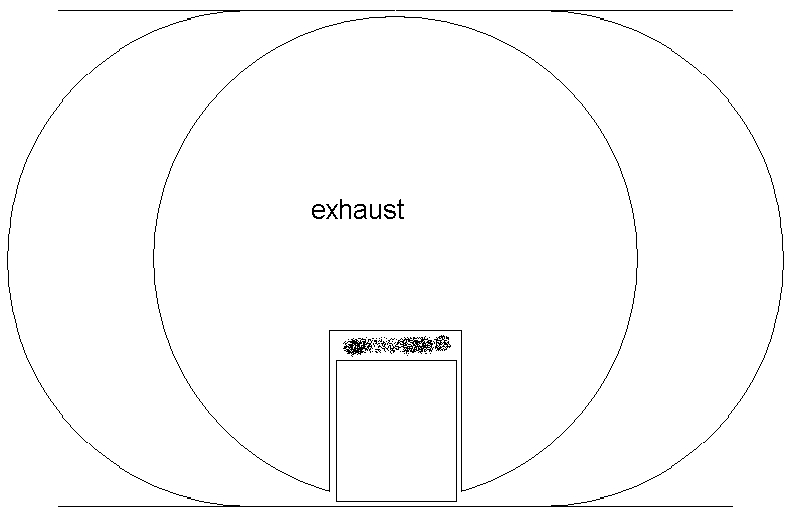

Cooling is now more difficult

lubrication is now more difficult

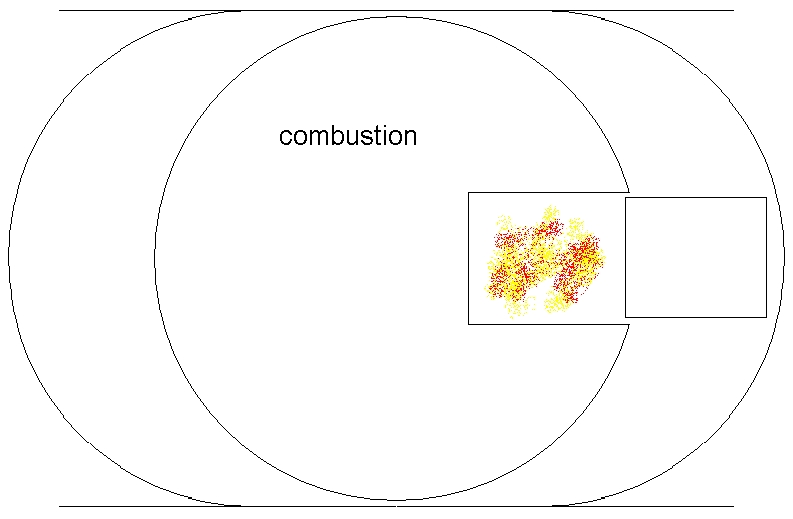

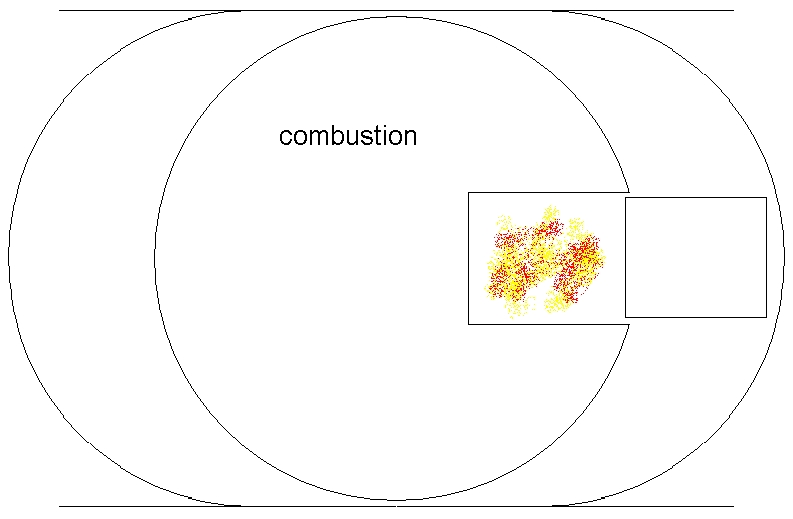

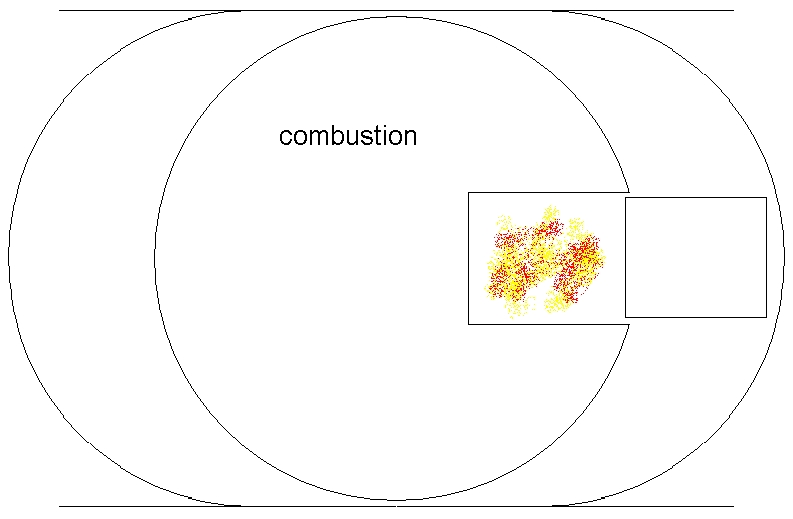

I imagine combustion efficiency would be poor with a sparkplug all the way to the side of the chamber.

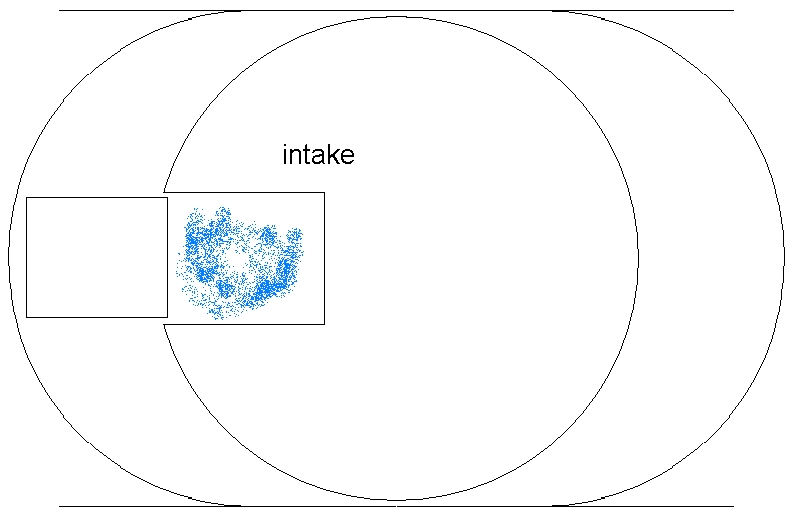

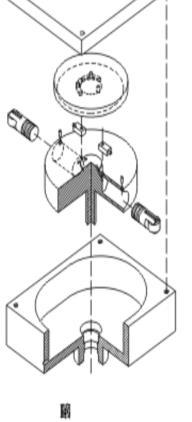

Although it appears to be somewhat of a rotary without the sealing problems (now that there are pistons), the side plate with ports in it for intake and exhaust will still mean side rotor leakage.

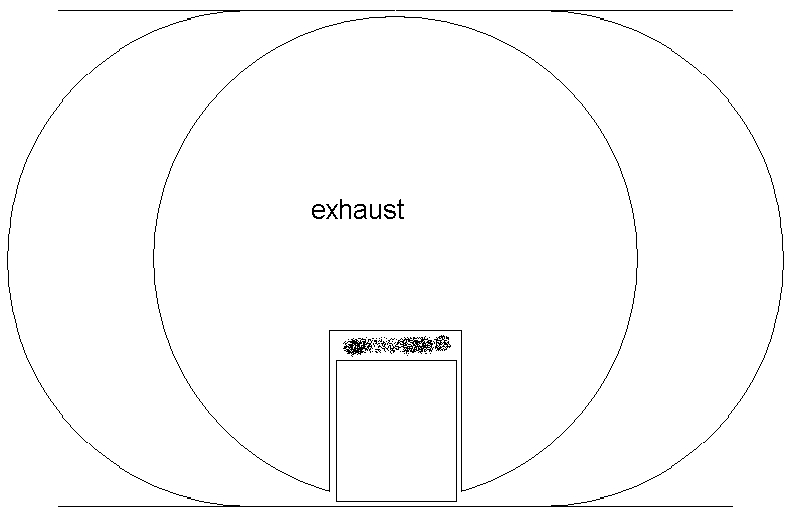

i see nothing from keeping the piston 'lofting' at the end of the exhaust stroke meaning a limitation in rpm and or reliability. Certainly a spring in the combustion chamber couldn't be considered.

The only thing good is a lot of efficiency could be gained back by having a much longer power stroke then compression stroke much like the Miller cycle. But variable valve timing makes that a reality in engines today without complicated crank systems.

'engine and turbo guy'

Cornell 02-03

Sorry but it aint new.

A rebirth of a design hailing from the very dawn of the automotive era and similar to the actual working of a diesel injection pump built by CAV sometime in the 1960's

If I could be bothered (and I can't) I would do a google search and see what comes up.

Any takers?

Pete.

It looks like an inside out radial engine...

Wesley

OU Sooner Racing Team Alum '09

connecting-rods.blogspot.com