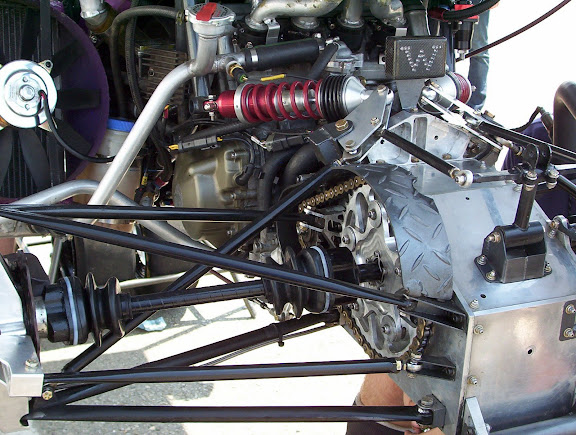

So it looks like a lot of schools flatten the ends of the A arm tubing when using spherical bearings on the outer side. I assume the reason for this is to reduce the depth of the bearing cup for clearance reasons. A couple pictures of what I'm talking about are found below:

Now, I know that a tube will fail near the middle due to buckling, but I'm wondering about how the change in shape effects the strength of the tubing. What are people's experiences with this design?

|

|

Reply With Quote

Reply With Quote