Josh,

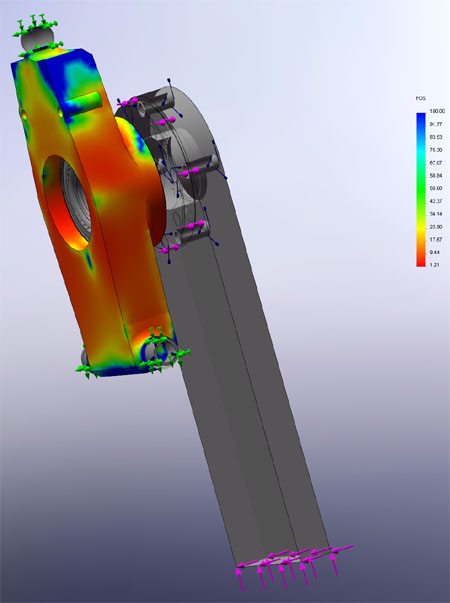

I think the loads will be applied to half of circumference in case of (Fx and Fz).

Fy will be transmitted from the bearing to the bearing shoulder on the upright

http://help.solidworks.com/2015/engl...stribution.htm

Someone correct me if I'am wrong.

|

|

Reply With Quote

Reply With Quote